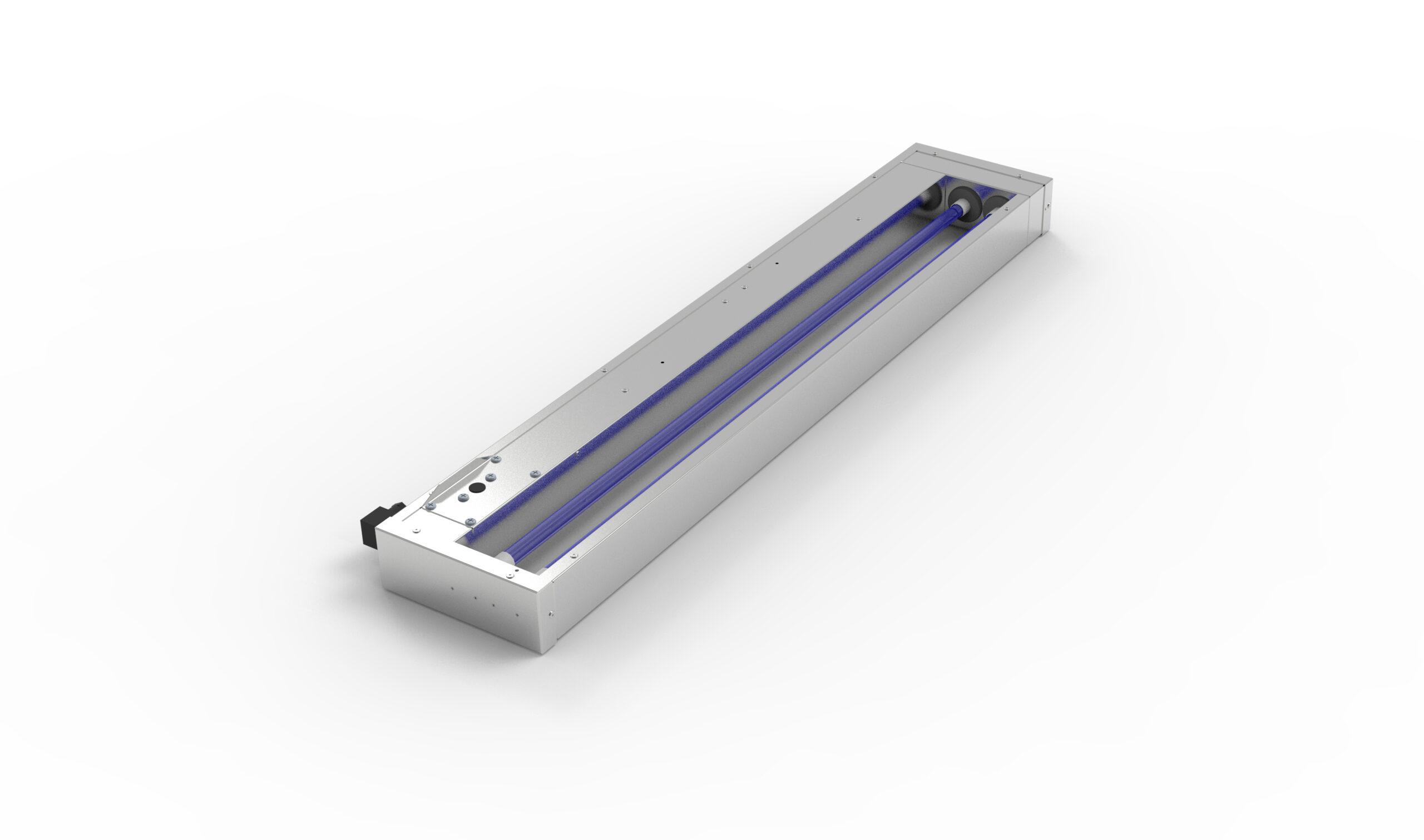

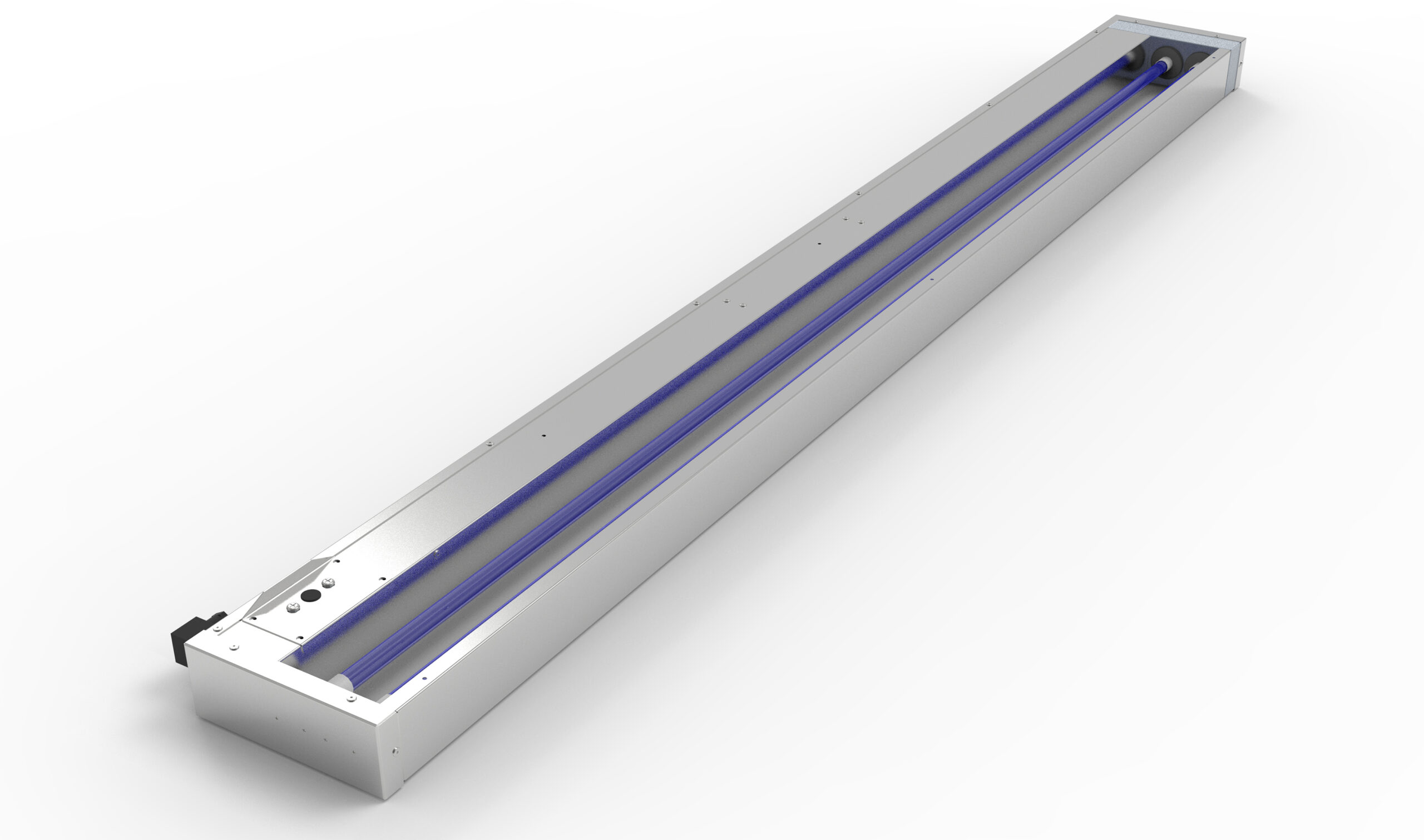

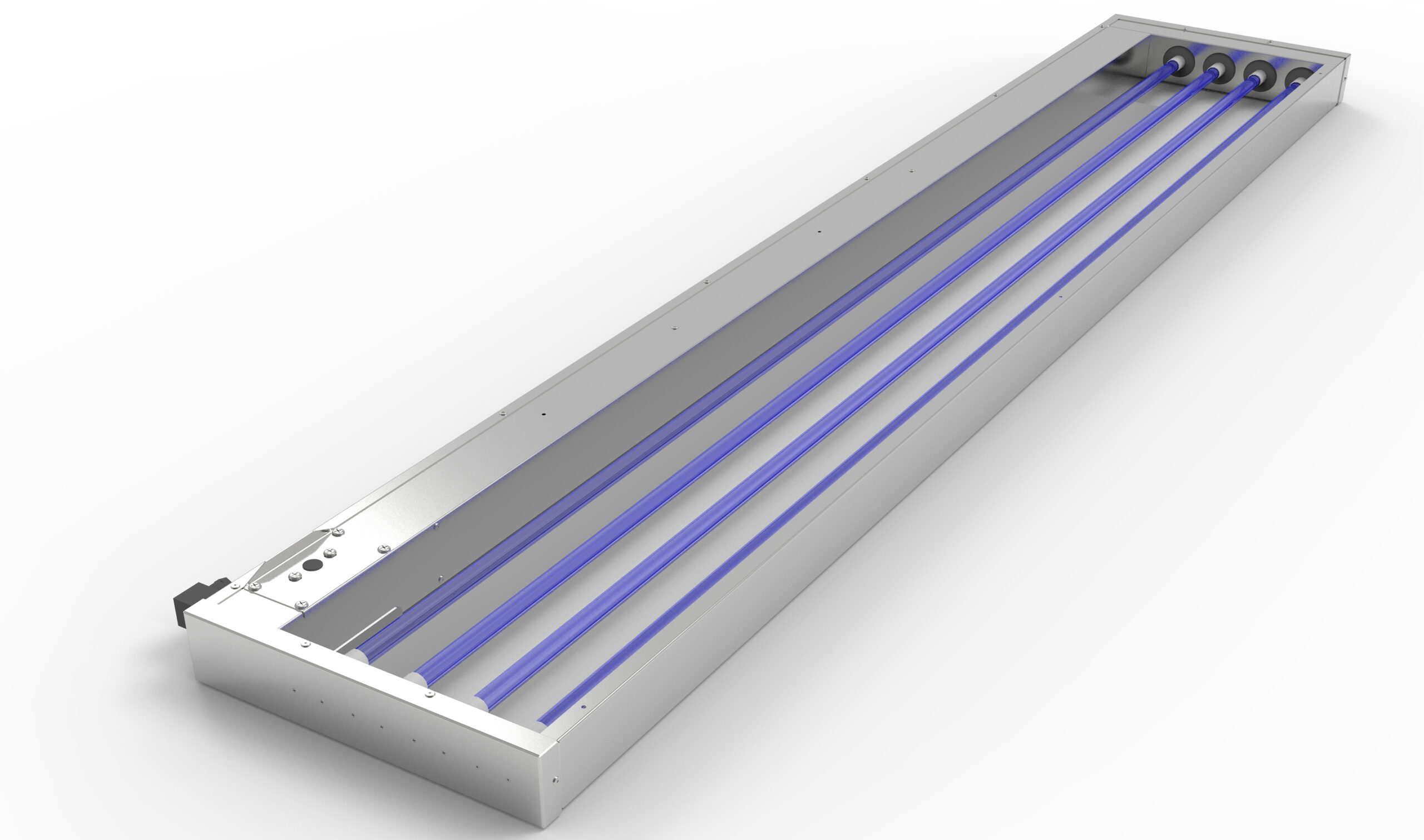

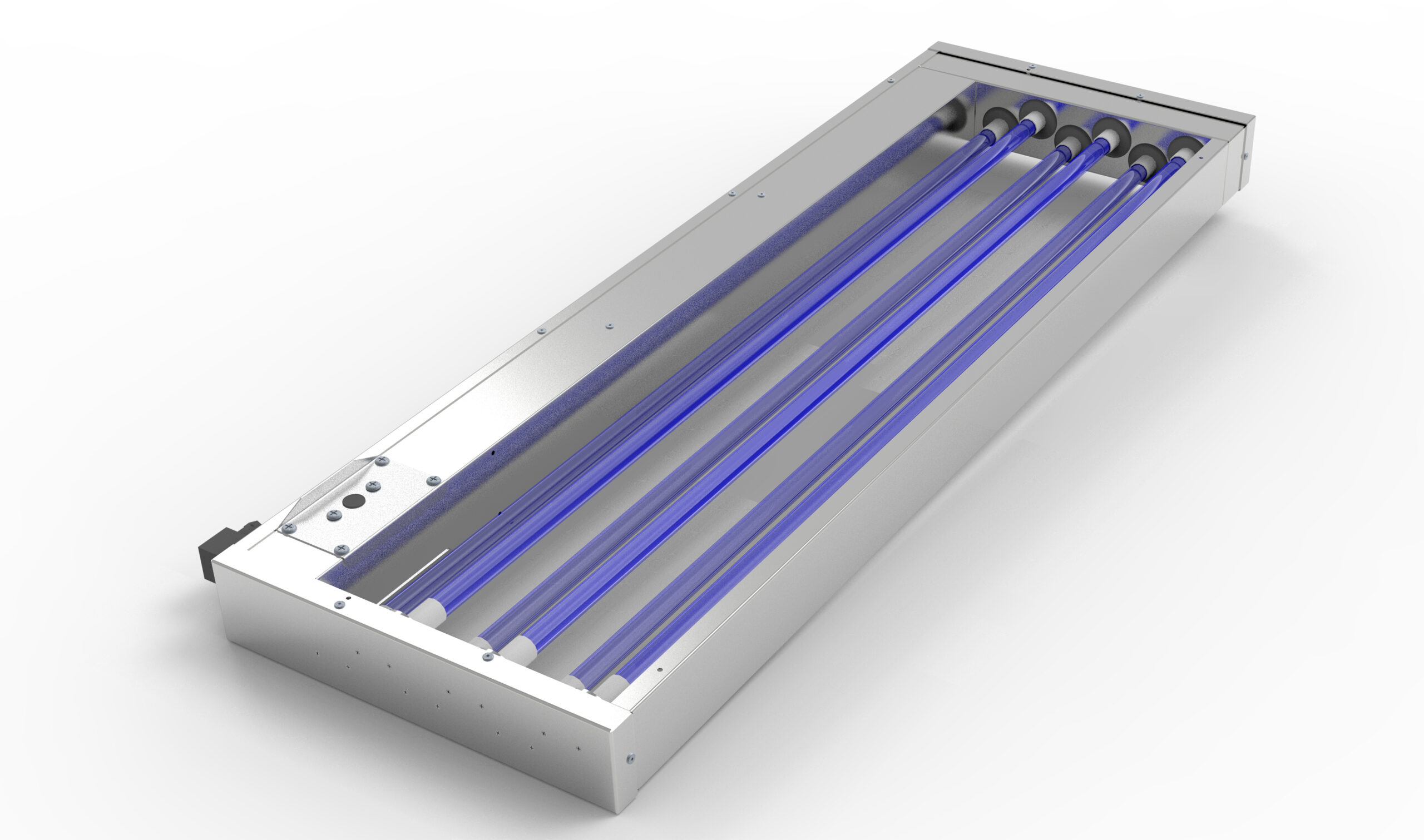

The ZERO+ air purifier with UV light and ozone is designed to meet the challenges of commercial kitchen ventilation, such as grease deposits and odour problems. The air purifier is designed for easy maintenance and cost-effective servicing.

ZERO+ is mounted directly in the filter housing of the ventilation cabinet, keeping the entire ventilation system clean of grease, and the UV tubes are easily accessible for wiping. When serviced, the UV tubes are replaced more quickly and easily than standard fluorescent tubes, saving both time and money.

UVtech ZERO+ is used to prevent grease build-up in the ventilation system and reduce cooking fumes that can disturb neighbours. The UV light breaks down grease molecules into harmless and non-sticky polymerised carbon compounds, keeping ventilation ducts free of grease.

The installation of ZERO+ leads to a reduction of sweeping and cleaning costs by 70-75 %. In addition, the grease-free exhaust air makes it possible to install heat exchangers in the restaurant's ventilation system, saving hundreds of thousands of kilowatt hours annually on heating.

ZERO+ also solves the problem of complaining neighbours by reducing the odour load in the exhaust air by 74-95 % when combined with cartridge carbon filters. This reduces nuisance odours and improves the working environment for both staff and neighbours.

The purification equipment can be integrated into a new ventilation hood or built into an existing one. ZERO+ complements a well-functioning ventilation hood with efficient mechanical grease filters, such as cyclone or labyrinth models.